Satellite Assembly, Integration & Testing

Empowering your constellation with reliable, efficient, and cost-effective AIT solutions

Overview

The rapidly evolving space industry is ushering in a new era of connectivity, visibility, and global governance, driven by next-generation satellite constellations. These advanced networks are transforming communications, Earth observation, and security on an unprecedented scale. Ananth Technologies is here to empower your constellation with reliable, efficient, and cost-effective Satellite Assembly, Integration, and Testing (AIT) solutions. With cutting-edge infrastructure and deep expertise, we ensure your satellites are mission-ready to shape the future of space.

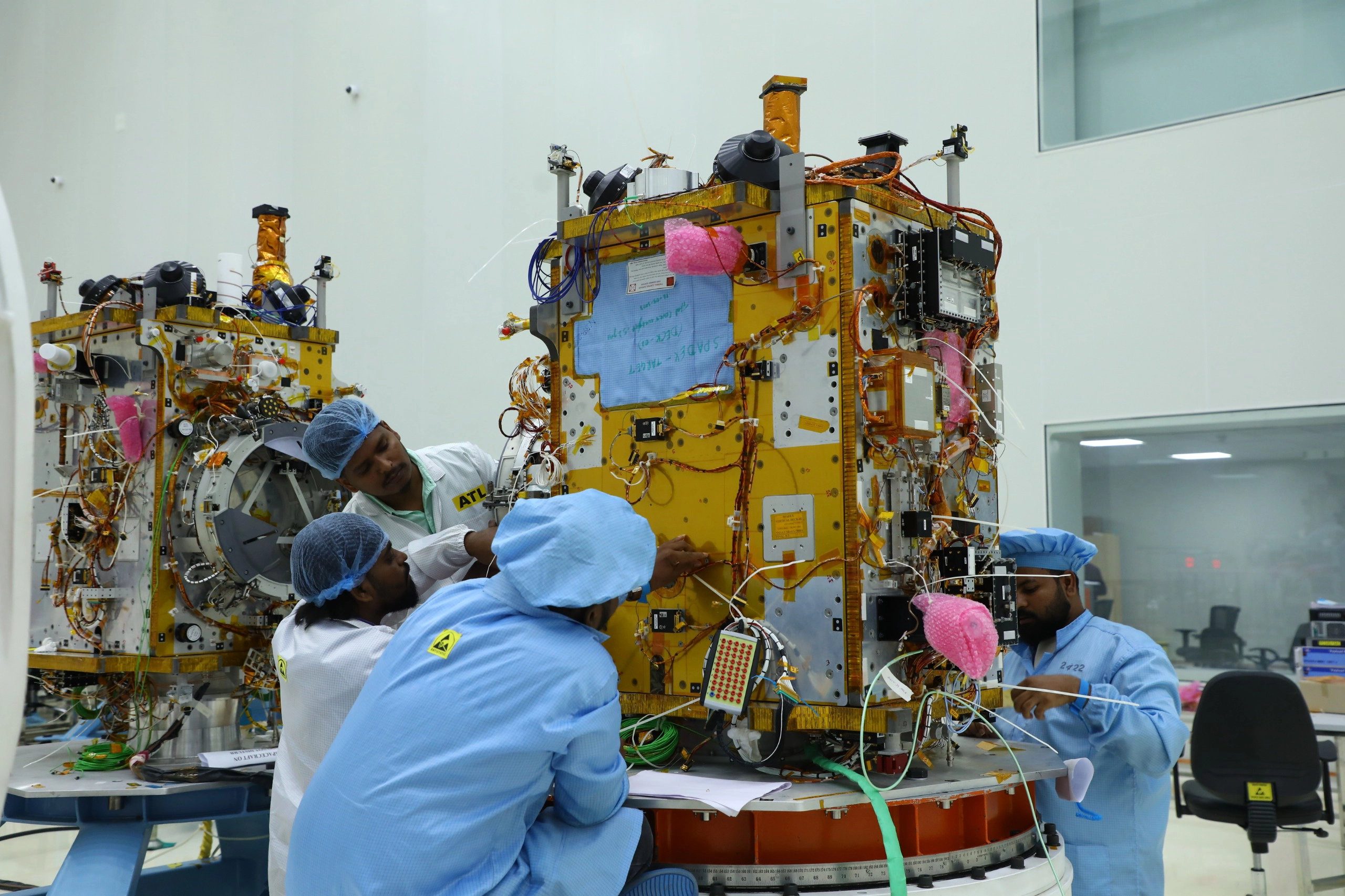

ATL's advanced Assembly, Integration, and Testing (AIT) infrastructure is designed to support complex spacecraft development with precision and effciency. Staffed by experienced professionals, our facilities deliver both tailored AIT services and comprehensive "AIT as a Service" solutions to meet diverse mission requirements.

World-Class AIT Facility

Ananth's Satellite AIT Facility is built to take spacecraft from concept to countdown with precision and confidence. Designed for end-to-end Assembly, Integration, and Testing, the facility combines advanced cleanrooms, specialised tooling, and rigorous quality processes to support small, medium, and high-complexity satellites. With deep heritage across launch vehicles and space missions, Ananth delivers reliable, schedule-driven AIT—ensuring every satellite is integrated, tested, and ready for orbit.

Core AIT Operations

Multi-Scale Capability

Simultaneous assembly, integration, and testing small, medium, and large satellites.

End-to-End Solutions

Complete spacecraft lifecycle support from assembly to mission readiness.

Quality Assurance

Rollout of space worthy system, ensuring fully functional and reliable build, with compliance to engineering conventions and standards.

AIT Success Stories

Delivering quality satellites on schedule for domestic and international customers

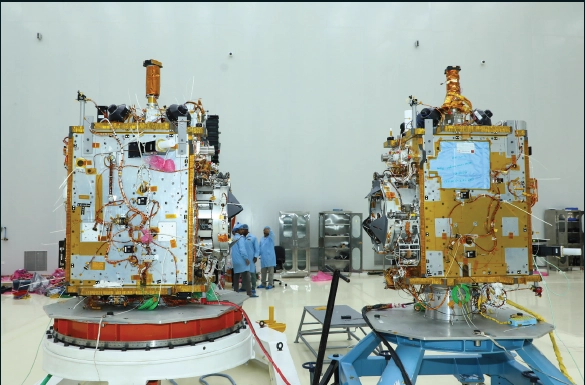

SpaDEX

2x220kg satellites

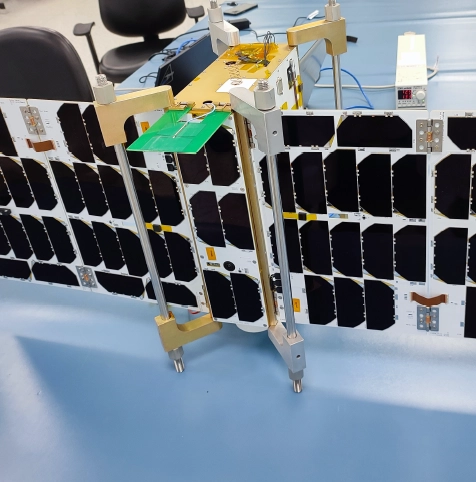

Janus-1

6U CubeSat

Elevation-1

6U CubeSat

Drishti

175kg satellite

AIT Facilities

Environmental Control Systems

- ISO-8 cleanroom for contamination-free assembly

- Precision temperature & humidity control

- Advanced HVAC with HEPA filtration

- ISO-9 spacecraft Air lock

- ISO-9 ground checkout areas

Multidomain Testing

- Full system validation protocols

- CG-MI Measurements

- Seismic isolation platforms

- Precision alignment measurement

- Nitrogen and Compressed air supply

Mechanical Equipment

- Satellite Handling Fixtures

- Heavy-duty precision crane system

Safety and Security Systems

- Fire detection

- 24x7 Video Surveillance

- Manned Security

Support Services

- Ground Checkout Stations for comprehensive system validation

- Solar Array Deployment with zero-gravity simulation

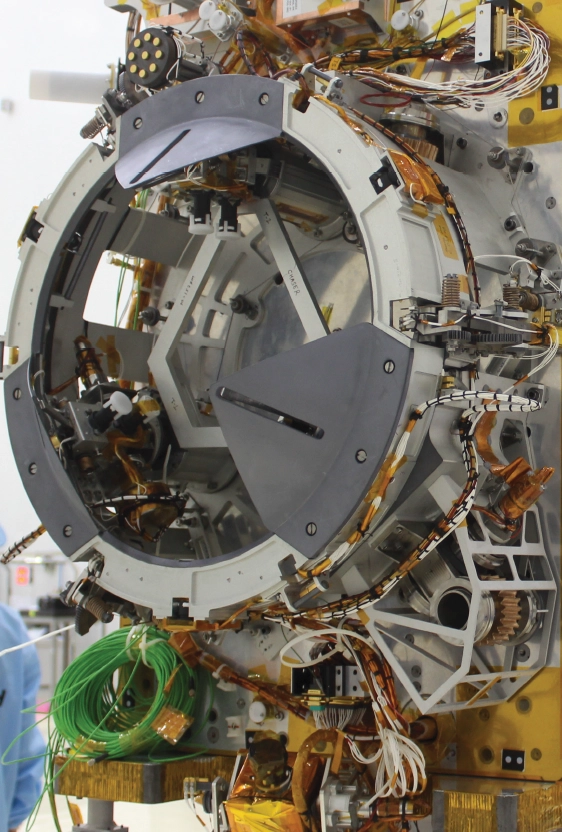

- Optical Payload Testing for precision instrument validation

- Satellite Alignment Measurements with high-accuracy positioning

- Expert Technical Support from trained AIT personnel and space engineering specialists

- Emergency lighting & UPS power

Environmental Test Facilities

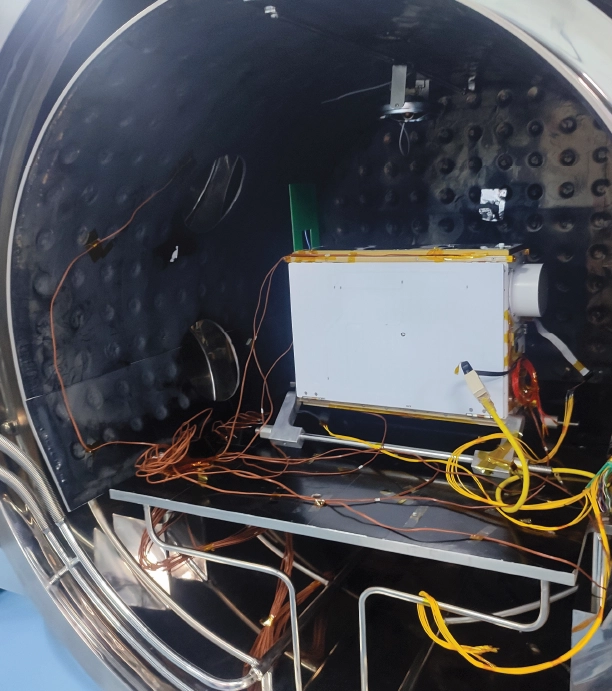

Thermal Vacuum Chamber

- Usable volume: φ 2.8m / L 2.2m

- Thermal range: -100°C to +100°C

- Vacuum: 1×10⁻⁶ milli bar

- Supports DUT of 1000 kg max

- Heat loads up to 4.5 kW max

- Dual zone thermal shroud

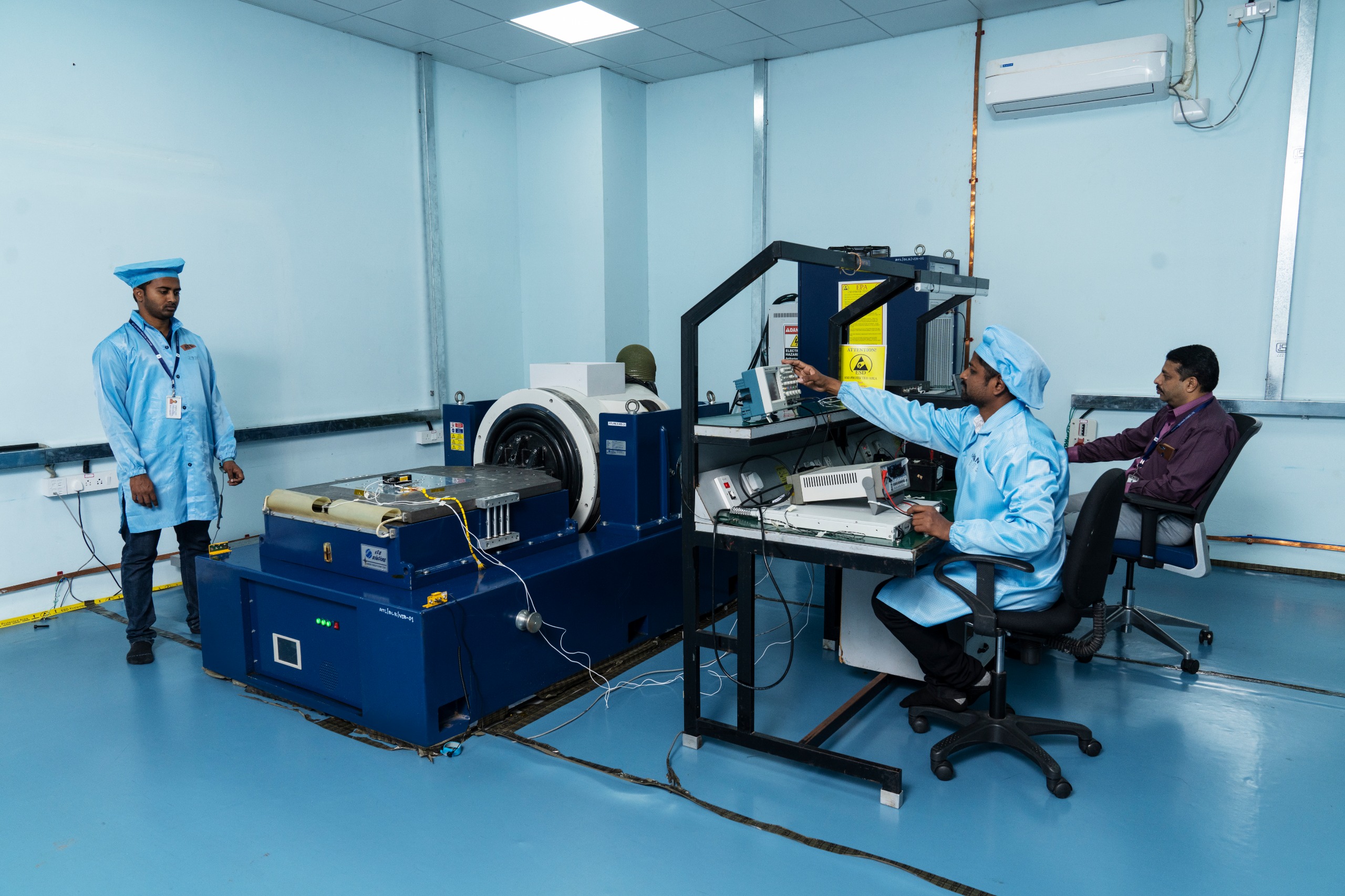

Vibration Testing

- High-force electrodynamic shakers

- Sine, random, and shock testing

- Multi-axis vibration capability

- Real-time data acquisition

- Qualification and acceptance levels

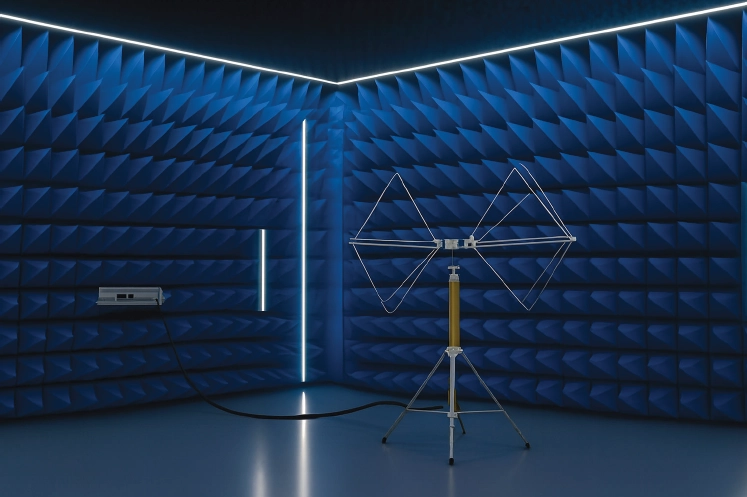

EMI/EMC Chamber

- Shielded anechoic chamber

- Radiated emissions testing

- Conducted susceptibility testing

- ESD evaluation capability

- MIL-STD and commercial standards