Overview

Ananth Technologies designs and manufactures high-performance solar panels for satellites ranging from CubeSats to advanced microsatellites. Developed at our Bengaluru space hardware facility, our solar panels combine flight-proven materials, precision engineering, and comprehensive environmental testing to deliver reliable power generation in demanding orbital conditions.

Key Features

High-Efficiency Triple-Junction Solar Cells

- GaInP/GaInAs/Ge triple-junction cells from leading international suppliers

- Efficiency up to 31%

- Integrated cover glass for radiation and particulate protection

Robust Electrical Design

- Magnetically clean layout to minimise dipole effects

- Parallel Gap resistance welding technique for solar cell interconnection

- Customizable string configurations (parallel / series)

- Built-in bypass and isolation diodes for shading protection

- Low-outgassing RTV silicone adhesive for solar cell bonding

Precision Mechanical Structures

- Multiple substrate options: PCB / FR-4 for CubeSats, CFRP plate + FR4 flex for larger configurations

- Aluminium honeycomb with CFRP face skins for microsatellite and large-format panels

- Space-grade hinges, hold-and-release mechanisms, and deployment systems

Customizable Interfaces

- Flexible mounting hole patterns and panel dimensions

- External temperature sensors with configurable I²C addresses

- Micro-D electrical connectors with custom bracket options

Applications

- Communication satellites

- Earth observation satellites

- Navigation satellites

- Scientific missions

- CubeSats and nanosatellites

- LEO constellations

Specifications

- Cell Type: Triple-junction GaAs

- Efficiency: Up to 31%

- Operating Temp: -60°C to +110°C

- Radiation Tolerance: 1E15 e/cm²

- Mission Life: 15+ years

- Large Panel Size: Up to 1.5m × 2.5m

- Power Density: ~230-250 W/m²

Testing & Qualification

Every solar panel undergoes rigorous qualification and acceptance testing, ensuring mission reliability from launch through long-duration space operations.

- Visual, dimensional, and mass verification

- Continuity & insulation resistance testing

- Electro-luminescence (EL) imaging for solar cell micro crack detection

- Vibration & mechanical shock tests

- Thermal vacuum and thermal cycling

- Sun simulator (I–V curve) testing

- Post-environmental functional performance testing

Product Portfolio

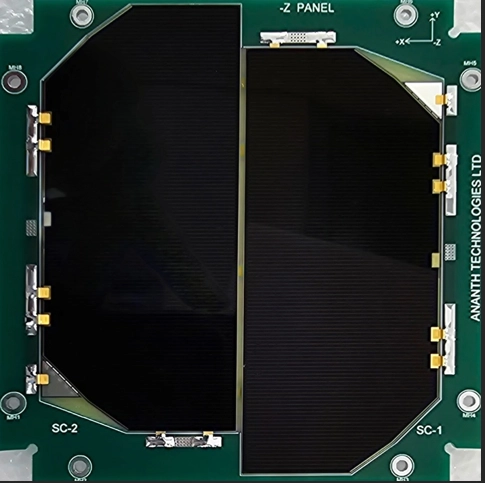

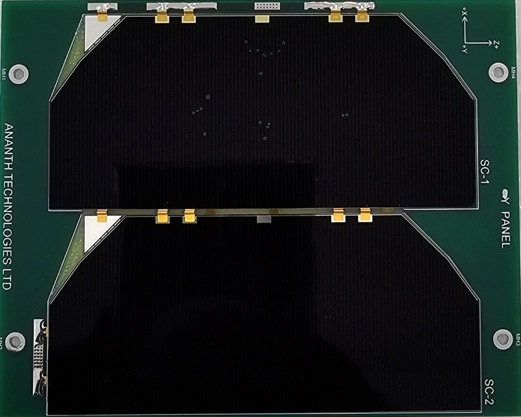

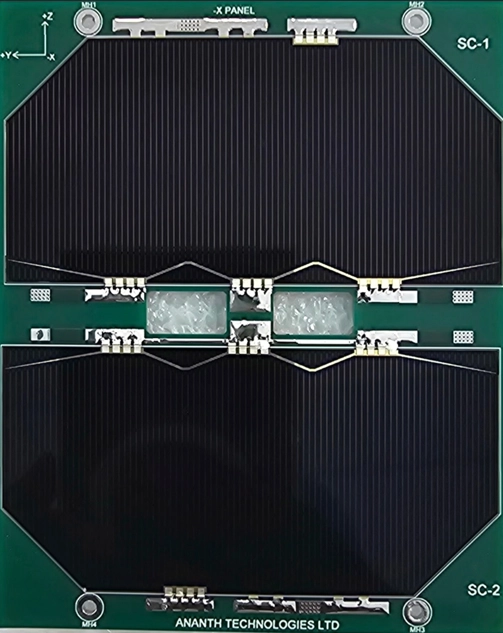

CubeSat Solar Panels (1U–16U)

Substrate: PCB, 2 cells in series, Pmax: ~2W, Size: 83 × 103.2 mm

Size: 206.5 × 321.3 mm, Substrate: FR-4, 5S × 3P configuration

CFRP plate + FR-4 flex circuitry, Size: 336 × 205 mm

Microsatellite Solar Arrays

Customised deployable solar arrays for microsatellites up to the 100-kg class and beyond.

- Aluminium honeycomb core with CFRP face sheets

- Precision-engineered hinges and deployment mechanisms

- Temperature sensors, sun sensors, and isolation diodes integrated

- Deployed frequency greater than 2 Hz for stability

Large-Format Satellite Solar Panels

For advanced satellites requiring high power, based on aluminium honeycomb structures with CFRP skins.

- Dimensions up to 1.5 m × 2.5 m

- Power Output: ~230-250W per square meter

- Lightweight: ~2 kg per square meter of array blanket mass

- Optimal balance of stiffness, weight, and performance

Customization Capabilities

Whether for a CubeSat, micro-satellite, or a next-generation LEO constellation, Ananth delivers solar panels precisely tailored to mission requirements.

- Panel geometry and size

- Solar cell type and configuration

- Deployable array mechanisms

- Connector and harness layout

- Mechanical interfaces and hinge systems

- Thermal design and sensor integration

- Full documentation, testing, and qualification support